Are there any friends curious about the production process of tin boxes? Usually, the tin packaging is made of tinplate material, through the printing process to print the exquisite artworks; cutting the tinplate into the specified specifications; then stamping by punching machines, and finally assembling and packaging. Today let’s learn about the production process of the tin box!

- Prepare tinplate: Generally, the main material of the tin box is tinplate. After the customer confirms the order, the most suitable tinplatewill be orderedbased on variety, size, thickness, and so on. The tinplate is usually stored directly in the printing factory. On the identification of the tinplate quality, it can usually be visually measured to see whether the surface is scratched or not, whether there are rust points, the thickness can be measured by the equal micrometer, and the hardness can be felt by hand.

- Printing: the confirmed design and layout drawings are given to the printing factory, and then the printing factory will arrange the tinplate printing, usually a sample will be providedto the printing factory to check the colors. In the process of printing, we should pay attentionthat whether the printing color matches the sample, whether the setting is accurate, whether there are stains, whether there are scars, and so on. These problems are generally responsible for the printing factory.

- Cutting material: After the tinplate printing, we need to cut the material with the cutting machine according to the cutline.

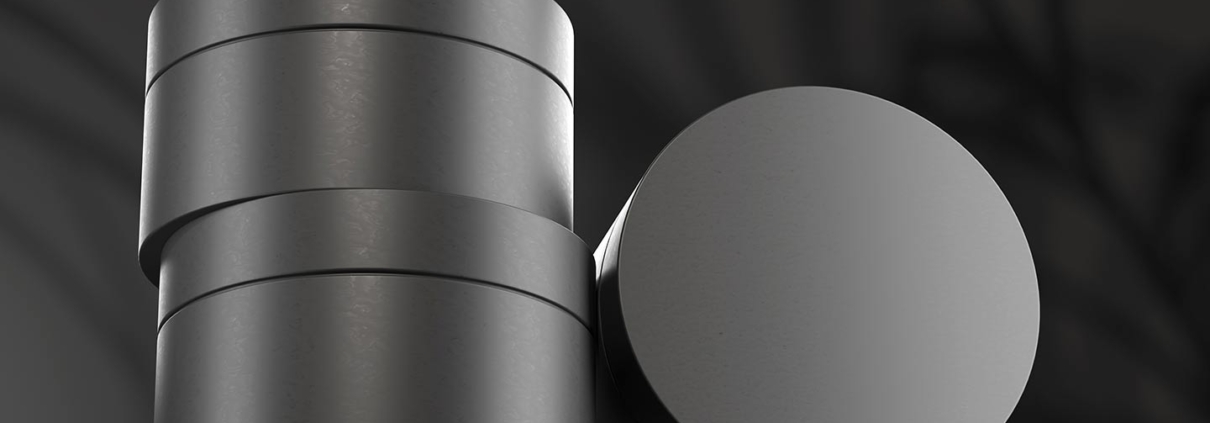

- Punching: It is the most important job of making a tin on the punching machine. Generally, tin must be divided into many processes to complete. The punching processwillusually bring the largest damage to the product. So the engineer and QC will check the tin box quality every half an hour on the production line. To make sure the mold and machine condition is as good as the beginning to avoid quality problems.

- Packaging: After the production is finished, the packaging department is responsible for cleaning and assembling. All tins will go through the oven and be cleaned by a cleanroom. In order to make sure all tin boxes arrivedin good condition, we will put each tin into a PP bag, then into a master carton. Each layer is separated by dividing cards, and wooden pallets if needed.